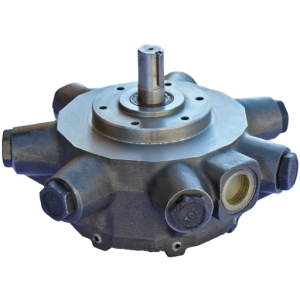

| Model | CM3/REV | P.MAX (bar) |

Q NOM(1/min) | R.P.MMax | Max drive power(Kw) | Shaft size(mm) | Weight(Kg) |

| PR 210 | 14.5 | 450 | 21 | 1450 | 18 | 24 | 20 |

| PR 270 | 19.0 | 450 | 27 | 1450 | 24 | 24 | 20 |

| PR 320 | 22.2 | 450 | 32 | 1450 | 28 | 24 | 20 |

Operation guide

1. The hydraulic oil level should always be higher than the pump level.

2. Before connecting the pressure pipe to the system, start the pump for a few moments so that the air inside the pump is completely drained.

3. The pump shaft can rotate in two directions (left and right).

4. A suitable filter should be installed in the oil return circuit to the tank with a hole of 20 microns and cleaned every 500 working hours.

5. A suitable filter with a 125 micron hole should be installed at the head of the suction pipe inside the tank and cleaned every 500 working hours.

6. Install the air filter on the tank lid and clean it every 200 working hours.

7. The tank lid should be completely sealed to prevent the penetration of dust and pollution.

8. The inside diameter of the oil suction pipe should be one size larger than the diameter of the pump inlet.

9. If you see any kind of vibration and abnormal sound in the pump, stop working.

10. Type of oil: use hydraulic oil with an average temperature of 55 degrees.